Pickard Steel from simple fabrication to complex structure. We see it through from start to finish

About Contact

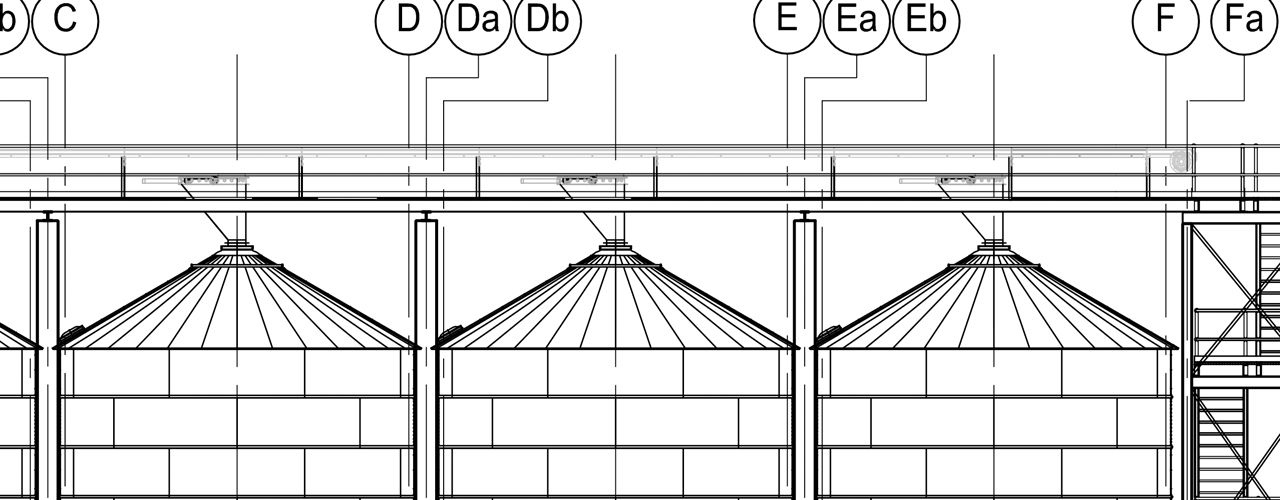

Having an expansive workshop area with vast height ensures the largest projects can be fabricated and assembled without prior restrictions. Limitless yard and storage space enables bulk stock for efficient turnaround of projects. Our workshop consists of numerous giant overhead cranes, various fabrication equipment and machinery, shot blast and paint facilities.

Close

Pickard Steel’s in-house workshop and welding supervisor ensures all welding is executed either as specified by the structural engineer or to the highest standard, meeting AS/NZS 1554.

Pickard Steel offers the following welding methods::

| Metal Insert Gas (MIG) and Metal Active Gas (MAG) Welding | Is a welding process in which an electric arc forms between a consumable wire electrode and the work piece (metal), which heats the work piece (metal), causing them to melt, then join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. |

| Flux Cord Arc Welding (FCAW) | Is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid slag protecting the weld. The process is widely used in construction because of its high welding speed and portability. |

| Manual Metal Arc (MMA) Welding | Manual arc welding process that uses a consumable electrode coated in flux to lay the weld. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapours that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination. |

| Tungsten Insert Gas (TIG) Welding | Is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-current welding power supply produces energy which is conducted across the arc through a column of highly ionized gas and metal vapours known as a plasma. |

| Air Carbon ARC Gouging | Is an arc cutting process where metal is cut and melted by the heat of a carbon arc. Molten metal is then removed by a blast of air. It employs a consumable carbon or graphite electrode to melt the material, which is then blown away by an air jet. |

Employees, contractors, and visitors are the number one priority at Pickard Steel.

Safety on site, in our workshop, and in our offices is a shared responsibility. All employees understand and appreciate the importance of following all documented safety procedures. Regular ongoing risk assessments, together with safe planning of work, takes place in our workshops and on site to identify hazards. We then take appropriate steps to ensure the safety of everyone involved.The employment of a professional QHSE Manager and Safety Co-ordinator ensures all new employees are immediately inducted. The induction process highlights to employees the requirement to follow procedures, identify risks and hazards, and familiarises them with evacuation and emergency procedures.

| Aldinga Shopping Centre | - Aldinga |

| Bartels Street Apartments | - Adelaide |

| Brice Metals | - Wingfield |

| Bunnings Trade Centre | - Gepps Cross |

| NTP Forklifts Australia | - Gepps Cross |

| Pickard Building Supplies | - Windsor Gardens |

| Tackle World | - Adelaide |

Pickard Steel are capable of earthmoving, mining, construction, quarry equipment repairs and maintenance. In addition, work including loader and excavator repairs, maintenance, plus various bucket and tipper repairs.